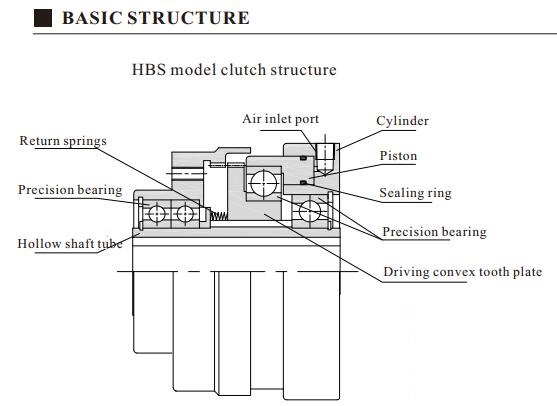

The power supply is air pressure. After supplying air pressure, piston pushes driving convex tooth plate moving towards to and combining driven concave tooth plate, both ends of teeth engagement to come into an integrated structure, clutch linked. Driving convex tooth plate and driven concave tooth plate are separated by return springs after exhausting air pressure, both ends of teeth separated, clutch released.

HBS mode Pneumatic tooth clutch is a kind of inside tooth Pneumatic clutch, it developed from outside tooth clutch. After supplying Pneumatic pressure, two ends of tooth engaged in axial movement; after exhausting Pneumatic pressure, two ends of tooth back by return springs. This tooth clutch is usually used in high precision industries.

HBS mode Pneumatic tooth clutch working theory:

Usually, driving tooth plate is rotated with driving shaft, while driven tooth plate is not like that. After supplying Pneumatic pressure, piston pushes driving tooth plate moving towards to and combining driven tooth plate, both ends of tooth integrated, to come into an integrated structure, clutch linked. Power output through driven tooth plate. Driving tooth plate and driven tooth plate are separated by return springs after exhausting Pneumatic pressure, both ends of tooth separated, clutch released.

HBS mode Pneumatic tooth clutch main characters:

1. Engaged with two ends of tooth, it is very suitable to mounted on various driving shaft, will not slippage with Pneumatic pressure. Compact size while transmit torque is several times than other same size clutches.

2. Inside return springs, separated thoroughly, no idling rotating friction load.

3. Linking and releasing in moment, controlled by Pneumatic pressure.

4. Integrated structure, easy installation and no worry about coaxiality.

5. Inside tooth structure, can prevent dust effectively.

6. Dry and wet working environment both can be work.

7. Tooth engagement, low speed or static linking.

Following is the structure of HBS pneumatic inside and outside tooth clutch for your reference:

Copyright © 2026Pneumatic clutch, Pneumatic brake, Safety chuck All Rights Reserved.

Address:12F, No.488 Banting Road, Jiuting Town, Songjiang District, Shanghai, PRC, 201615

Tel:152-0180-5440 Fax: 021-57636570 Mobile:15201805440 E-mail:songyulu@sh-handong.com