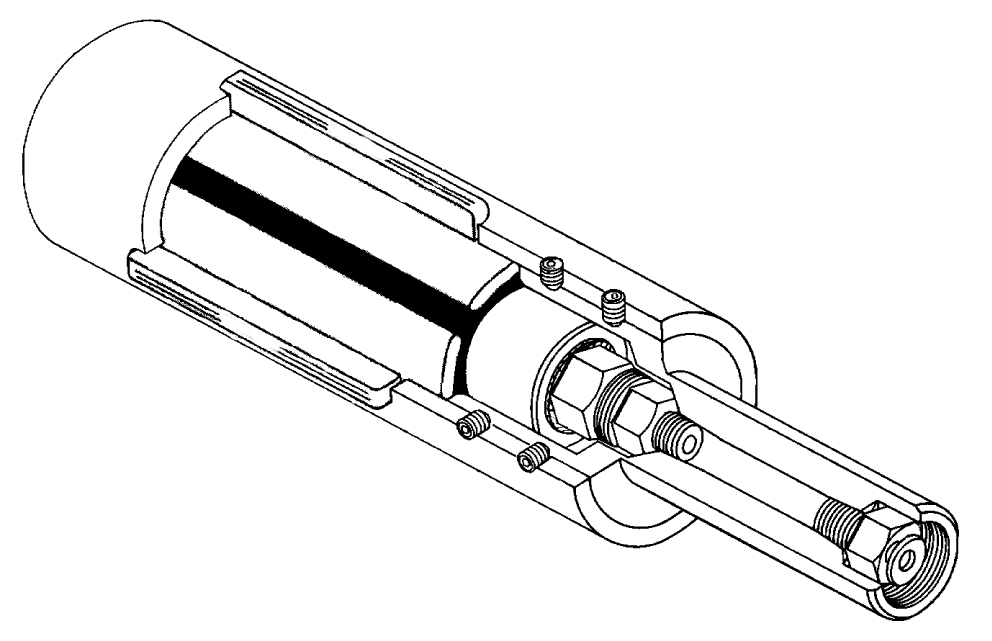

Pneumatic expandable shaft has the advantage of easy paper tube placing, economic, short charging time, heavy loading, simple maintenance and long service life and etc. It is widely used in printing machinery, paper making machinery and other winding and unwinding machine. It can be match with brake, clutch, pedestal safety chuck, tension controller and so on.

Pneumatic expandable shaft category:

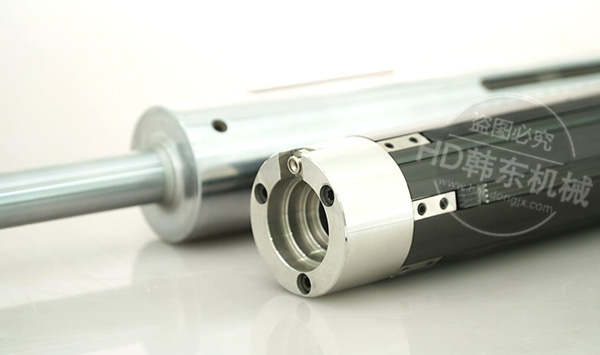

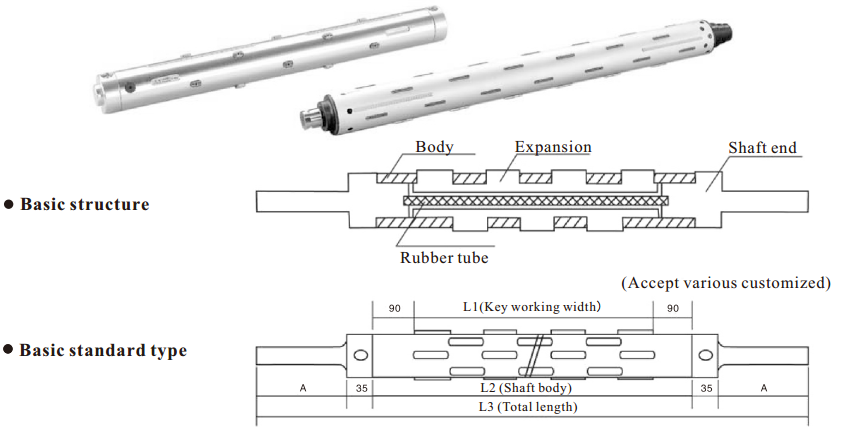

1. Lug type pneumatic expandable shaft

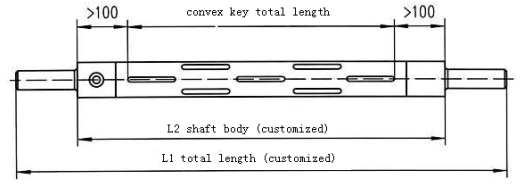

Shaft body uses superior steel pipe, chroming, aluminum convex key stretch flexible, rubber bladder, filling and exhausting gas nipple, good sealing effect, long service life, removable shaft head, convenient for maintenance. Lug type air shaft expanded is single key, fulcrum spreads to all the keys, so keep the shaft force balance. After filling air pressure, one side expanding height can be reached to 5mm to 6mm, it is suitable for heavy loading of winding materials.

2. Strip type pneumatic expandable shaft

Expanding part is the plates, fulcrum homodisperse, stress uniform, normally the expanding parts can reach to 4mm to 5mm, it is suitable for high precision winding machine or light material winding.

Pneumatic expandable shaft application:

Lug type pneumatic expandable shaft expanded is single key, fulcrum spreads to all the keys, so keep the shaft force balance, suitable for light material winding. It is application for slitting, printing, coating, laminating, bag making, paper making and other relevant winding and unwinding machinery, energy conservation and efficient.

Pneumatic expandable shaft

Pneumatic expandable shaft has the advantage of easy paper tube placing, economic, short charging time, heavy loading, simple maintenance and long service life and etc. It is widely used in printing machinery, paper making machinery and other winding and unwinding machine. It can be match with pneumatic brake, clutch, pedestal safety chuck, tension controller and so on.

According to its material, this pneumatic expandable shaft can be divided into steel and aluminum two modes.

1. Steel pneumatic expandable shaft. For mechanical structures, it used steel pipes. They have enhanced durability as well as strong resistance against abrasion and shocks.

2. Aluminum pneumatic expandable shaft. It is made of aluminum, the products are lighter than those made of steel. Moreover, they give excellent handling.

These steel and aluminum pneumatic expandable shaft are mainly applied to clamp and hold paper core, plastic core or other cores. It is extensively applied in coating, slitting, printing, rewinding, paper making, bag, plastic and other relevant machineries winding and unwinding. It is economic, enhance productivity and safety operation.

Lug type pneumatic expandable shafts are strong and versatile, delivering superior performance in the widest range of converting unwind and rewind applications. Also, eliminate core damage, prevent roll slippage during fast startups and shutdowns, and minimize vibration at high web speeds.

Pneumatic expandable shaft working theory and main characters:

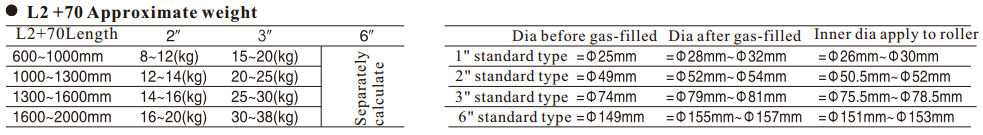

1. Air pressure shaft also called pneumatic expandable shaft, it uses air pressure changing shaft outside diameter size, so as to closely touch with reel pipe. So as to convenient whole roll material winding and unwinding, making production line operation reasonable, convenient, precious and automatic.

2. When air inlet, shaft inner expanded, components of inner shaft expanded, the shaft outside diameter increase, so the reel pipe touched with shaft closely. When air outlet, expanded components withdraw, shaft can be taken out easily.

3. Shaft core uses high stress steel or aluminum alloy, internal expand components adapts import synthetic rubber, and has various structure types: Strip type air shaft, Lug air shaft, Multi bladder air shaft.

Copyright © 2026Pneumatic clutch, Pneumatic brake, Safety chuck All Rights Reserved.

Address:12F, No.488 Banting Road, Jiuting Town, Songjiang District, Shanghai, PRC, 201615

Tel:152-0180-5440 Fax: 021-57636570 Mobile:15201805440 E-mail:songyulu@sh-handong.com