BTCL-10 model pneumatic tooth clutch is a customized clutch, based on BTC model clutch with longer shaft.Pneumatic tooth clutch (pneumatic shaft tooth clutch) making precious transmission to be a possible, it can be used in wet and slippery hard working environment. Compact size, while can transmit large torque in narrow space. It should be make sure there is a distance between two ends of tooth during this clutch, so as to no gear grinding when idle rotating. BTCL-10 clutch is the customized based on BTC-10, extension the shaft length, widely used in customized automation, packing and printing machinery and etc.

BTCL-10 model pneumatic tooth clutch main characters:

1. It is linked with air pressure via shaft movement, released by return springs.

2. Tooth and tooth engagement transmits torque, no slippage, precision torque transmission.

3. Narrow space it can transmit high torque in compact size, torque adjustment range is wide.

4. Compact size, while transmit torque is several times than other same size clutch.

5. 1:1 constant value, no slippage and no torque lost.

6. Instant integrate or separate, action flexible and rapid.

7. Integrated structure, easy installation and no worry about tooth and tooth coaxiality.

8. Low speed or static engagement, high speed rotating.

BTCL-10 model pneumatic tooth clutch (customized)

Pneumatic tooth clutch (pneumatic shaft tooth clutch) making precious transmission to be a possible, it can be used in wet and slippery hard working environment. Compact size, while can transmit large torque in narrow space. It should be make sure there is a distance between two ends of tooth during this clutch, so as to no gear grinding when idle rotating. BTCL-10 clutch is the customized based on BTC-10, extension the shaft length, widely used in customized automation, packing and printing machinery and etc.

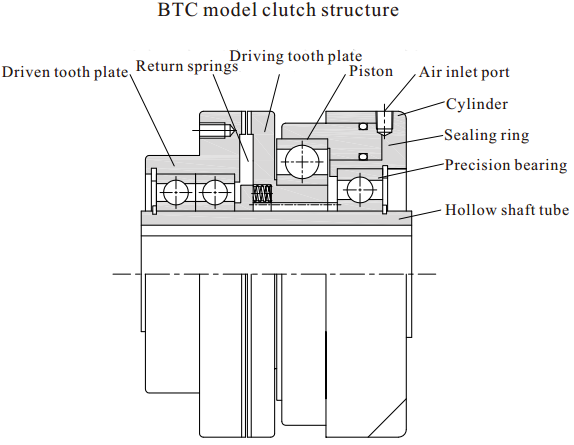

BTCL-10 model pneumatic tooth clutch (customized) working thoery:

This clutch is linked with air pressure, released by return springs. After supplying air pressure, piston pushes driving tooth plate to slide along the direction of the axis, driving tooth plate compressed driven tooth plate to come into an integrated structure, clutch linked. Driving tooth plate and driven tooth plate are separated by return springs after exhausting air pressure, clutch released.

BTCL-10 model pneumatic tooth clutch (customized) opetation precaution:

1. Connect rotation

Air cylinder and piston will be caused connect rotation by bearing, it can be use 3 pieces of stop grooves in 120° angle or auxiliary stop groove screw holes to fix or stop. Be careful, when they are stopped, cylinder shouldn’t be incline because of interference power, or it will affect clutch normal working.

2. Precaution when installation clutch onto shaft

It is better to use professional tool to inflate hollow shaft tube when install clutch onto shaft, don't hit cylinder or other easy wearing parts.

3. Belt pulley and gear installation

When install belt pulley or gear onto clutch driving cover, try to make sure radial force center of belt pulley or gear is align with two units of bearings'loading center of driving cover.Excessive incline will influence clutch service life.

4. Bearing lubrication

The trust ball bearing should be lubricated periodically. The period is between 1 to 6 months according to using occasion. Because the other bearings are sealed, there is no need to supply.

5. Avoid high load working

It is better to use double or triple safety factor when choose model, overload usage will reduce clutch service life.

Copyright © 2026Pneumatic clutch, Pneumatic brake, Safety chuck All Rights Reserved.

Address:12F, No.488 Banting Road, Jiuting Town, Songjiang District, Shanghai, PRC, 201615

Tel:152-0180-5440 Fax: 021-57636570 Mobile:15201805440 E-mail:songyulu@sh-handong.com