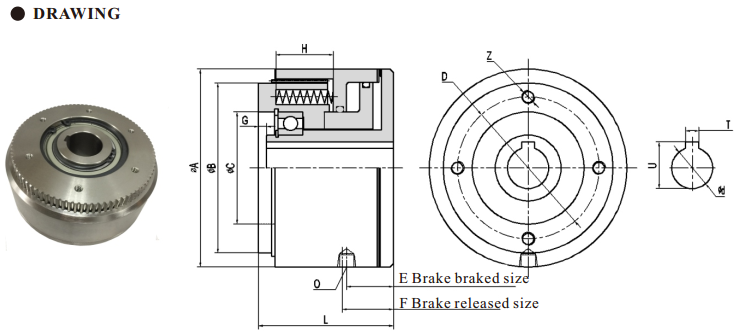

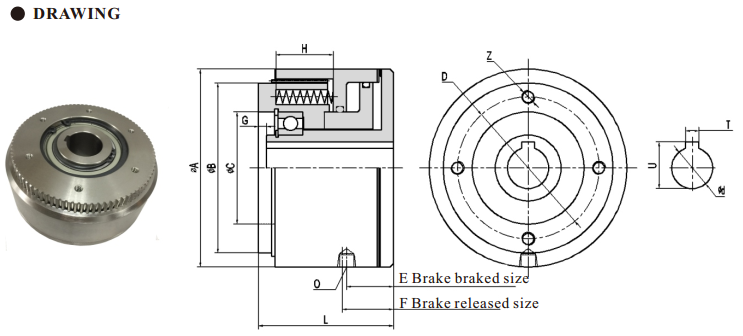

Normally, braking springs compressed both ends of piston end teeth and hollow shaft tube end teeth, brake braked. After supplying air pressure, piston moves back to compress braking springs, piston end teeth and hollow shaft tube end teeth are separated, brake released. After exhausting air pressure, piston end teeth and hollow shaft tube end teeth compressed again by braking springs, brake braked.

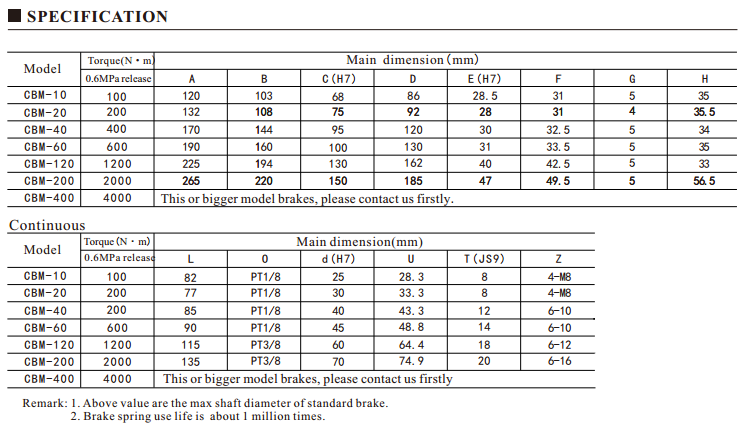

CBM model brake only used in low speed working situation

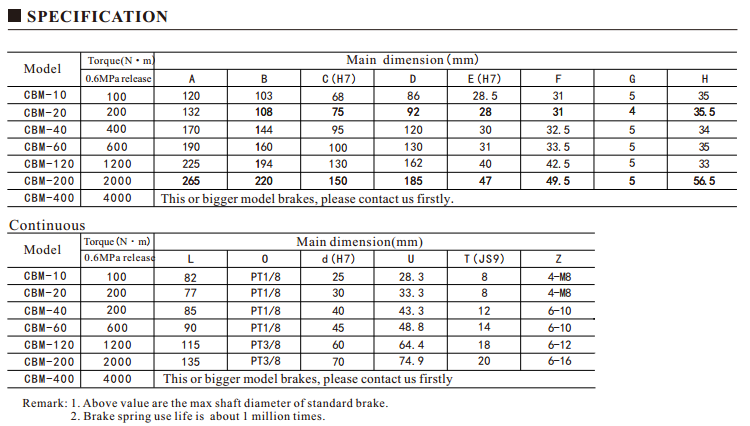

CBM model pneumatic tooth brake

This is a new technical tooth brake,it is suitable for urgent situation usage for sfety. It characters like this:

1.Use two ends of tooth engagement for braking, not easy slippage, braking large torque and no damage.

2.Braking and releasing can be finished in constant, can reach exact orientation.

3.Two ends of tooth use special process technology, high strength, good abrasion and long service life.

4.normal braking design.

CBM model pneumatic tooth brake installation precaution:

1. Mounted onto shaft

It is better to use professional tool to inflate hollow shaft tube when install clutch onto shaft, don't hit cylinder or other easy wearing parts.

2. Usage working situation

It is special suitable for long time braking and short time releasing working situation, rotating speed should be lower (0-10r).

3. Avoid high load working

It is better to use 1.5-2 times safety factors when choose model, overload usage will reduce clutch service life.

Copyright © 2026Pneumatic clutch, Pneumatic brake, Safety chuck All Rights Reserved.

Address:12F, No.488 Banting Road, Jiuting Town, Songjiang District, Shanghai, PRC, 201615

Tel:152-0180-5440 Fax: 021-57636570 Mobile:15201805440 E-mail:songyulu@sh-handong.com